When the engine was rebuilt I fitted a new old stock side draft carburetor trusting in the fact it would work smoothly. I experienced a problem with the car when it was first back on the road, total lack of performance and poor acceleration. I tracked this down to a sticking choke valve which was easily fixed with lubrication. However another problem with the carb was more persistent; this was a very slight fuel leakage from around the brass pipe which the fuel feed line is attached to.

General tapping in of the brass fitting made no difference and also the use of sealant gave little improvement. I resorted to removing the brass pipe from my old original carb, smearing it with Loctite and have now cured the leakage.

Originally focused on the restoration of my November 1961 built (1962 model year) Type 3 Karmann Ghia (343) I have now extended the blog to cover the ongoing ownership of my 1964 built (1965 model year) RHD type 3 Karmann Ghia (344) purchased in 1982.

Thursday, December 31, 2009

Sunday, December 13, 2009

More electrical issues resolved

The intermitent fault on the instrument cluster related to the ignition and oil warning lights looks to be linked to the wiring on the backing unit - I will dig out another from my stock and replace and hopefully this will resolve it.

I also established the fault with the fog lights was caused by a faulty relay via swapping across the one from my 65. Whilst I have 4 of these they all turned out to be useless so will be looking for one on The Samba.

This should solve the remaining electrical issues and the next snag to resolve is the drivers door window which separated from its lifter due to rust, will see what I have in stock.

I also established the fault with the fog lights was caused by a faulty relay via swapping across the one from my 65. Whilst I have 4 of these they all turned out to be useless so will be looking for one on The Samba.

This should solve the remaining electrical issues and the next snag to resolve is the drivers door window which separated from its lifter due to rust, will see what I have in stock.

Saturday, December 12, 2009

More electrical problems solved

The swap across to the later indicator flasher and wiring worked perfectly. Additionally I have tracked the grounding out of the horn to a faulty plastic washer that fits between the head of one of the 3 screws that hold the horn ring in place and the actual horn ring. I replaced it with a new piece of plastic and the horn no longer earths out and works as it is supposed to.

Next on the list is to resolve the ignition and oil lamp intermitent working.

Next on the list is to resolve the ignition and oil lamp intermitent working.

Sunday, December 06, 2009

Tweaking the electrics

The engine is back in place and clutch adjusted and the car seems to drive much better now as well.

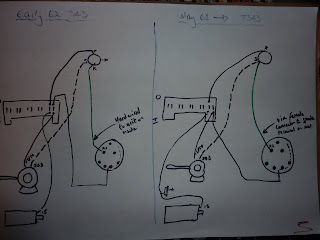

Next task is resolving some of the residual electrical problems. Something that I thought was a problem just turned out to be a difference in wiring between the early cars and those from slightly later. I noticed that when I put on the side lights for the car that the lower left green light on the indicator cluster\fuel gauge came on. As this indicator light is wired to the fog lamps on my 65 I thought there was a fault in the wiring; once I had consulted the wiring diagram it became clear that this is how it is supposed to work and that the function of the lower left green indicator lamp changed at some stage from showing side lamps switched on to showing fog lights on.

With that sorted I am tackling issues with the indicator wiring and relays. Again the 62 cars wiring differs and uses a flasher relay with 3 terminals (S,K, +) rather than subsequent ones that use only 2 (S,+). So far I have amassed a range of dodgy early style 3 terminal versions, none of which work to my total satisfaction. As I have a number of 2 terminal ones I thought I would change to this later system. From looking at the wiring diagrams it looks achievable which just a couple of wires to swap around. Here is a quick sketch of the 2 systems.

Tuesday, November 03, 2009

Clutch repair and manifold update

Well the engine went back in again at the weekend and there was a lot of fiddling about before it happened.

I ordered a replacement clutch release bearing shaft only for it to have the slot for the internal circlip set about 1.5cm further inboard from the clutch cable arm end; no supplier seemed to be able to supply the one I needed. I then remembered that Pete at Cogbox mentioned that there were heavy duty shafts available and a quick search for these turned up a pack by BugPack with the shaft, bearing and fittings. This also has the slot for the internal circlip in both places. These heavy duty shafts are far sturdier and offer a better solution for retention of the release bearing clips so hopefully I wont have a repeat episode with the clutch assembly.

The shaft bearing supplied is a neoprene one and needs to be cut to size through various attempts at inserting, marking and cutting. All this was carried out and the engine went back in effortlessly.

I now just need to adjust the clutch and cure a small leak on the fuel inlet into the carb; the brass fitting has come looses and even gentle tapping back into place hasn't cured it. I will dig out the locktight at the weekend and see if that cures it.

I also obtained a replacement 62 only manifold for the engine from Bert3 in Belgium. It turned out to be distorted where heat had been applied in an attempt to remove carbon deposits in the preheater pipe. A local engineering workshop got it back into line but I think it is still slightly out of true as when the engine is warm it seems to 'hunt' rather than idle smoothly. I might need to remove and tweak slightly.

I ordered a replacement clutch release bearing shaft only for it to have the slot for the internal circlip set about 1.5cm further inboard from the clutch cable arm end; no supplier seemed to be able to supply the one I needed. I then remembered that Pete at Cogbox mentioned that there were heavy duty shafts available and a quick search for these turned up a pack by BugPack with the shaft, bearing and fittings. This also has the slot for the internal circlip in both places. These heavy duty shafts are far sturdier and offer a better solution for retention of the release bearing clips so hopefully I wont have a repeat episode with the clutch assembly.

The shaft bearing supplied is a neoprene one and needs to be cut to size through various attempts at inserting, marking and cutting. All this was carried out and the engine went back in effortlessly.

I now just need to adjust the clutch and cure a small leak on the fuel inlet into the carb; the brass fitting has come looses and even gentle tapping back into place hasn't cured it. I will dig out the locktight at the weekend and see if that cures it.

I also obtained a replacement 62 only manifold for the engine from Bert3 in Belgium. It turned out to be distorted where heat had been applied in an attempt to remove carbon deposits in the preheater pipe. A local engineering workshop got it back into line but I think it is still slightly out of true as when the engine is warm it seems to 'hunt' rather than idle smoothly. I might need to remove and tweak slightly.

Saturday, September 12, 2009

Damage limitation

Got the engine out today, The clutch release bearing had come off the operating shaft, one arm on the shaft was bent and one broken. The springs on each of the 3 clutch release levers that are part of the clutch pressure plate had all come off and were wrecked.

Not sure now if it was a failure of the pressure plate that led to the release bearing and operating shaft damage or the other way round.

Will be ordering new parts and switching to the later style clutch release mechanism and pressure plate; at the same time we will also be checking the fly wheel to make sure there is no distortion that could have caused the failure.

At least no major damage to engine or gear box.

Not sure now if it was a failure of the pressure plate that led to the release bearing and operating shaft damage or the other way round.

Will be ordering new parts and switching to the later style clutch release mechanism and pressure plate; at the same time we will also be checking the fly wheel to make sure there is no distortion that could have caused the failure.

At least no major damage to engine or gear box.

Thursday, September 10, 2009

62 details

Here is one more difference on the early 62s compared to later ones.

I never looked at the 62 handles properly when I took them off and when sorting through my collection of door handles to supply one to another T34 owner I noticed that the back of the original 62 handles in the finger grip area are hollow, where as all the later ones are solid.

Post 62 handle at top, 62 at bottom in the photo.

And one more thing

To solve some of the electrical problems on the car and remove the need for a separate switch for the windscreen washers, as the valve in the push button unit leaks, I bought a NOS switch unit which was of course very expensive but looked great.

It solved some of the electrical glitched linked to the resistor on the back of the unit but the new valve in the washer switch leaks equally as well as the old one.

If any one knows how to repair these then do let me know.

It solved some of the electrical glitched linked to the resistor on the back of the unit but the new valve in the washer switch leaks equally as well as the old one.

If any one knows how to repair these then do let me know.

Happenings since May

It hasn't exactly been a smooth transition from restoration to on the road for my 62, in fact it's been more trial and tribulation.

On the way back from it's MOT after the VolksWorld show the rear driver's side wheel decided it didn't like being attached to the car and came off at about 30mph with the exception of one bolt that held the wheel to the car and stopped it scrapping along the ground. Outcome was no one injured, a damaged wheel, dented pride but no damage to the bodywork.

So having got over that I tracked down a replacement rim and will be prepping it to go on the car shortly.

Electrical problems have persisted, most of them now relate to the multi function instrument cluster and I will be swapping over the back of the unit to see if that helps solve the problems. I also had to swap the early MPH speedo back to the early restored KPH speedo as the trip meter kept zeroing back to 0 miles.

Subsequently has issues with the brake fluid proof hosing I bought to connect the reservoir to the piping and the joint between that pipe and the master cylinder pipe. It bled fluid profusely and I replaced it and bled the brakes which now seem OK.

At the VolksWorld show the car picked up a dent in one of the doors and at the same time the door lifter decided to part company with the window glass - will sort both of these problems at the same time. I will use a guy who does dent removal and then replace the window lifter and glass from my stock in the loft.

Finally - I was driving the car back from London along the A40, just before where it joins the M40, very busy in early evening and as I changed down gear the clutch release bearing, newly installed of course, decided to give way accompanied by loud banging and grating.

After 5 hours we were home, the engine is OK and turns over and the gearbox selects all gears. So hopefully damage is restricted to the bearing and shift lever inside the bell housing.

I have taken advice from ever helpful Luke at Terry's Beetles and will be switching the release bearing assembly and clutch to the later style with the aid of a conversion kit from Pete at Cogbox - more to follow on this as it happens.

Here is a picture of the car abandoned on the A40 with us safely out of the way.

On the way back from it's MOT after the VolksWorld show the rear driver's side wheel decided it didn't like being attached to the car and came off at about 30mph with the exception of one bolt that held the wheel to the car and stopped it scrapping along the ground. Outcome was no one injured, a damaged wheel, dented pride but no damage to the bodywork.

So having got over that I tracked down a replacement rim and will be prepping it to go on the car shortly.

Electrical problems have persisted, most of them now relate to the multi function instrument cluster and I will be swapping over the back of the unit to see if that helps solve the problems. I also had to swap the early MPH speedo back to the early restored KPH speedo as the trip meter kept zeroing back to 0 miles.

Subsequently has issues with the brake fluid proof hosing I bought to connect the reservoir to the piping and the joint between that pipe and the master cylinder pipe. It bled fluid profusely and I replaced it and bled the brakes which now seem OK.

At the VolksWorld show the car picked up a dent in one of the doors and at the same time the door lifter decided to part company with the window glass - will sort both of these problems at the same time. I will use a guy who does dent removal and then replace the window lifter and glass from my stock in the loft.

Finally - I was driving the car back from London along the A40, just before where it joins the M40, very busy in early evening and as I changed down gear the clutch release bearing, newly installed of course, decided to give way accompanied by loud banging and grating.

After 5 hours we were home, the engine is OK and turns over and the gearbox selects all gears. So hopefully damage is restricted to the bearing and shift lever inside the bell housing.

I have taken advice from ever helpful Luke at Terry's Beetles and will be switching the release bearing assembly and clutch to the later style with the aid of a conversion kit from Pete at Cogbox - more to follow on this as it happens.

Here is a picture of the car abandoned on the A40 with us safely out of the way.

Friday, May 15, 2009

May 2009 update

Well at long last the registration for the car came through. It is now finally road registered and taxed under registration number 278XUT. I have a set of number plates on order in the correct period style from Vintage Supplies and they should be with me next week.

Here is an image of the VW birth certificate which has a few interesting things on it.

- It states that paint code L41 isn't simply black but Tukan black - never seen it described this way before

- There is an explanation of the M codes - not provided on my previous certificates

- M580 is shown as a pearl white roof, so the car was 2 tone originally

Strangely they can no longer put the engine number on the certificate for data protection reasons - No idea what the logic on this is, whoose data are they protecting and why would they want it protecting? They do however confirm your original engine number in the accompanying letter.

I now have the final pieces of carpet for the car, thanks Joel for the templates, and have also had the sill pieces made up with the correct heater outlet grommets, will be fitting these shortly.

Finally I went to the Stanford Hall event and whilst I didn't find any amazing NOS parts I stumbled across a couple of small items on my Friend Brian Johnsons stand which he gave me for free - a couple of original plastic end caps for the wiper spindles and a plastic seal for the door lock - really small parts but some nice final touches.

A small picture of the car also appears again in Volksworld this month as the Car that the editor, Ivan, would most have liked to take home with him - good man Ivan!

Sunday, April 05, 2009

April news

The car passed its' roadworthy test (MOT) at the end of the week. Just waiting for the birth certificate from VW to be able to submit the registration papers for road use in the UK.

I have a few mechanical adjustments to make following the ride back from the testing station, adjust the clutch cable conduit and tweak up the rear brakes amongst them. Additionally I have some remaining trim pieces to work on, but more of them as they take place.

I have a few mechanical adjustments to make following the ride back from the testing station, adjust the clutch cable conduit and tweak up the rear brakes amongst them. Additionally I have some remaining trim pieces to work on, but more of them as they take place.

Monday, March 30, 2009

Final March updates

In the lead up to finishing the car for the show I received the part carpet set from Newton Commercial. fantastic fit and great quality. I prepared templates for them as in a previous post and they than scanned them and laser cut the material. the only small problem was they can't reproduce the correct sill heater outlet grommet but are looking at reattaching my old ones.

meantime I received the templates for the tunnel and cros bulkhead pieces from Joel in the Us and handed them to newton at the Volksworld show, so should have the carpets back soon.

other work was mainly around fit up of the interior panels, I have a problem to resolve on one of the door cards as it is too large but other wise everything fits really well.

As mentioned the electrics were a challenge, we still have to get the foglights to work at the correct time and the indicator lights on the dash to work correctly, this is because I don't have a functioning early flasher unit and later ones are slightly different. My local auto electrician has a cunning plan to get around this though.

Things left to do are mostly to rectify the above and then get the car roadworthy tested and registered.

March, and what an update

Well, March has been all go, trying to get the car finished for the Volksworld show - did i manage it, well of course! It was a close run thing and the car ended up going down on a trailer, late night oil was burned with a local auto electrician resolving various electrical gremlins but unfortunately the new battery I had ordered for the 62 didn't arrive and the one on the 65 chose this moment to die. In any case the car wasn't registered for road use in the UK so couldn't be driven.

So it entered the show under human power but left with its new battery connected under its own power, was driven around the outside of the show ground and back home on its trailer - a great feeling after 6 years of hard work.

Here are some shots of it inside the show, I have a short video to post as well shortly and an update on some of the final work undertaken, plus some small remedial actions still needed.

Saturday, February 28, 2009

February update 3

Here are a couple of shots of the car. I have fitted out the drivers door and fixed it to the car, still need to adjust the window etc.

Also fixed the problem with the passenger side rear vent window. The car goes into the body shop this week for some minor work while i am away so hopefully when I get back all paint\body issues will be sorted.

I have installed the scratched rear window for the time being but Mark Poulton has kindly donated one to the project - thanks Mark!

Once I get back it will be the final push to finish the car before the end of March.

Saturday, February 21, 2009

February update 2

Well I haven't had time to blog because I have been rebuilding frantically. I am working hard to get the show finished and present at the Volksworld show here in the UK at the end of March.

So what have I been doing?

- Revisiting the wiring loom and sorting a few issues

- Rebuilding the rear drivers side hub seal and brakes

- Fitting fuel lines and heater cables

- Replacing the oil filler neck which turned out to be bent and wouldn't allow me to insert the dip stick

- Refitting the gear lever & steering wheel & headlights

- Fitting the fronts screen and wipers

- Trying to fit the rear screen only to find it was very badly scratched and too poor to use - I am on the search for one in the UK and if you have a good quality none heated rear window then post a comment

- Fitting and finishing trimming of the passenger door and A & B posts

- Making templates for a new set of 62 specific carpets, some pieces have rough estimates of where exact location of items are, I am waiting for some templates to arrive from Joel in the US to help resolve, thanks Joel. Meanwhile the templates have gone off to Newton Commercial who alreadfy manufacture carpets for various VWs that include original style grommets for all appropriate appertures - I'll let you know how they turn out

- Taking advice from Paul at Brackley Paint on how to tackle a few minor body issues (some self inflicted during the rebuild) the car goes back to them in a weeks time whilst I am working abroad so that will be excellent timing

Sounds so easy but it has been hard work and loads left to do, so posts will be a bit sporadic while I press on.

Here are some pics of the car and the carpet templates - only items on the passenger side and centre are shown as the drivers side are of course mirror images and the templates can be reversed.

Tuesday, February 03, 2009

February update 1

I have been struggling to fit the upright chromed pillar that the rear vent window hinges off. There has been much swearing and gentle, and not so gentle, bashing, removing of excess chrome plating, paint and thickness of rubber in the new rear vent seal.

I think I am about there with it now but needed then to remove it all to trim the B post edge.

I have also fitted the rubber\aluminium strip that goes from the rear roof pillar base to base of the front roof pillar, including using the new rubber base strips that I picked up at the VW Classic in the US during 2004.

Finally the passenger door has ben fitted and just needs a little tweaking to get the gaps perfect. So next is finish off a few small things on the passenger side then turn the car around and start on the other side. I need to push on with this as I am hoping that during a week's vacation in the middle of Feb I can finish the majority of the fit out and get the car MOTd (road worthy test) ready for display at the Volksworld show at the end of March.

I think I am about there with it now but needed then to remove it all to trim the B post edge.

I have also fitted the rubber\aluminium strip that goes from the rear roof pillar base to base of the front roof pillar, including using the new rubber base strips that I picked up at the VW Classic in the US during 2004.

Finally the passenger door has ben fitted and just needs a little tweaking to get the gaps perfect. So next is finish off a few small things on the passenger side then turn the car around and start on the other side. I need to push on with this as I am hoping that during a week's vacation in the middle of Feb I can finish the majority of the fit out and get the car MOTd (road worthy test) ready for display at the Volksworld show at the end of March.

Thursday, January 22, 2009

Roof lining finished

I managed to finish the roof lining at the weekend and have also installed the NOS sun visors bought individually from Paul Colbert and BerT3 at a far more reasonable price than currently advertised by Lars Neuffer whose prices simply reflect the ever escalating price of NOS parts.

I have also installed the correct aluminium stemmed early rear view mirror extracted out of my stash of parts as the one that came on the car was from a 6o's beetle.

Sunday, January 11, 2009

Further interior trim progress

I have now finished fitting the trim to the rear parcel shelf area and rear shoulders\B pillars in the original style for a 62 model.

I have also retrimmed the front screen pillars and fitted the NOS front screen pillar aluminium trims.

Next for completion is the head lining which I hope to complete during the week.

Saturday, January 10, 2009

Rear parcel shelf

I have been working on the rear parcel shelf area and have used the material kindly supplied by Lee Hedges when he sources the materials for the interior from TMI and had the seat covers made up.

A stiff card under liner was made and attached to the underneath of the lining to prevent the corrugations in the rear parcel shelf showing through.

I have also had to spend a lot of time making a shaped material cover for the small rear shoulder area in front of the parcel shelf. On the early models these were covered with material, later ones had a seperate black plastic cover or it was an intergrated part of the cover that goes below the opening rear quarter light.

I have glued the rear parcel shelf in place and fitted the resprayed rear vent but have yet to glue the shoulder covers on or glue down the front edge of the shelf as it is -5C and the material isn't pliable enough even with heat applied to it to get a good fit.

Wednesday, January 07, 2009

A head lining for the New Year

I have started work on installing the head lining. It is a bit of a jig saw because you need to put the A & B post trims on first, plus the B posts needed new card liners making beforehand.

Additionally covers need to be made for the small shoulder areas on the 62 models in matching vinyl to the rear parcel shelf as they weren't fitted with plastic covers of any description. More on this in the next post.

I made a new insulation felt liner for the roof and stuck it firmly in place and have put the new liner in just by its 3 fixing bars (longest at rear) whilst I do the other trim.

Subscribe to:

Posts (Atom)

video of our 65 on the motorway

video of our 65 on the M40 taken by Paul Donovan https://m.youtube.com/watch?v=Y5pXVCcqGfA

-

It is 50 years today since my Type 34 rolled off the production line at the Karmann factory. Since leaving Germany it has lived in Denma...

-

Theresa and I drove both of our type 34s to the 50 years of the Type 34 celebration in Germany - I don't think there was any other hus...